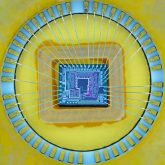

für die Entwicklung

für die Entwicklungund Produktion von Mikrochips

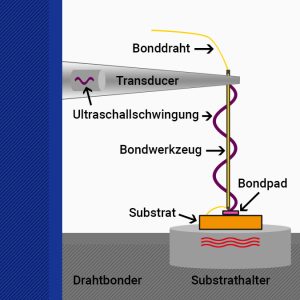

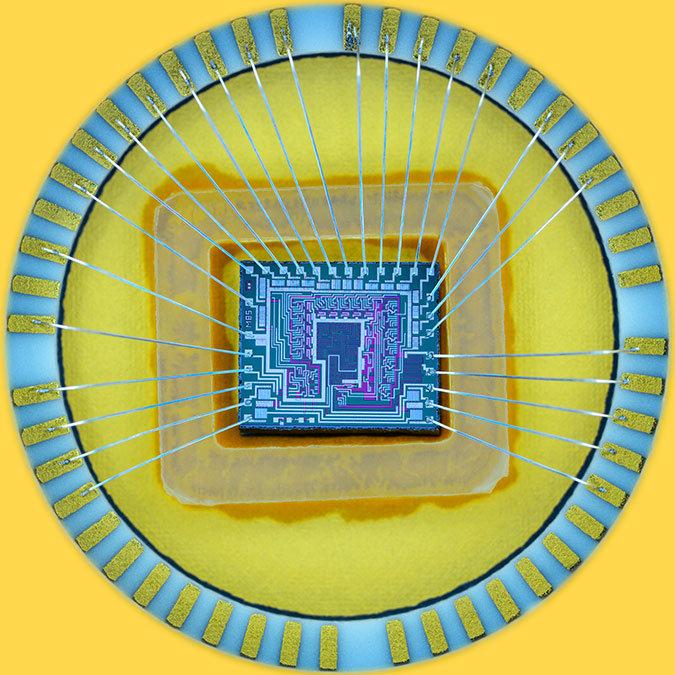

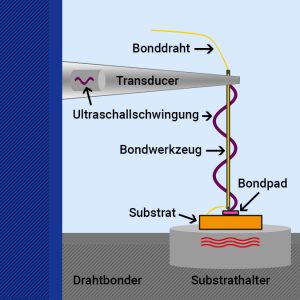

DRAHTBONDER

DRAHTBONDER

alle Draht- und Die-Bonder

im Überblick

alle Draht- und Die-Bonder

im Überblick

DRAHTBONDER EXPERTEN

DRAHTBONDER EXPERTEN

mit motorisierter XYZ Achse

mit motorisierter XYZ Achseund drehbarem Bondkopf AUTOMATISCHER DRAHTBONDER

mit motorisierter

mit motorisierterZ- & Y- Achse DICKDRAHTBONDER

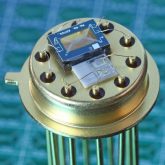

Chip-Bonder

Chip-Bonderzum Platzieren von Mikrochips

DIE-BONDER

DIE-BONDER

OKTOBERFEST

OKTOBERFEST

in

Germany

zum Beispiel auf der Weltleitmesse

für Entwicklung und Fertigung von Elektronik